Solution-Dyed vs. Stock-Dyed Material

As you shop for vehicle or outdoor furniture covers, you’re likely to come across terms referring to the dying process of the material. But what do “Solution-Dyed” and “Stock-Dyed” really mean, and does it even matter?

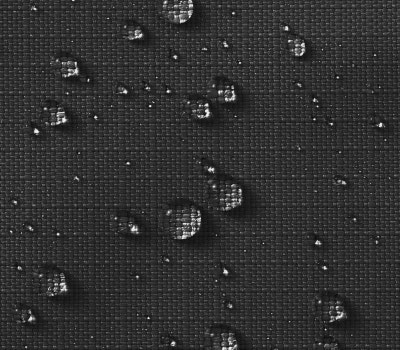

Polyester Fabric

The majority of high-quality outdoor covers are made with polyester. When the terms solution-dyed and stock-dyed (also referred to as “piece-dyed”) are used, it is safe to assume that the material is made from polyester or a polyester blend.

Polyester is a synthetic fabric that begins as a polymer melt in liquid form. This liquid undergoes polymerization to create long fibers, or threads. The fibers are then spun together to form a strong, durable material.

Polyester is a synthetic fabric that begins as a polymer melt in liquid form. This liquid undergoes polymerization to create long fibers, or threads. The fibers are then spun together to form a strong, durable material.

Polyester fibers at the Coverstore factory

The Solution-Dying Process

As mentioned above, polyester starts in a liquid form. When a material is marked as “solution-dyed”, this means that the color for the finished product was added during this liquid stage. After the color is mixed into the polymer melt, it is cooled and spun as usual. This allows the color to be completely integrated into the material, resulting in a more vibrant and long-lasting color. When exposed to intense sunlight and other weather conditions, solution-dyed materials will retain their color and strength for a longer period of time. This makes them have excellent fade and stain-resistance, as well as great durability.

Solution-dyed material is also eco-friendly, as no water is used during the process and energy output tends to be less. Stock-dyed material can use 1-3 gallons of water per yard of material produced.

Solution-dyed material is also eco-friendly, as no water is used during the process and energy output tends to be less. Stock-dyed material can use 1-3 gallons of water per yard of material produced.

The Stock-Dying Process

The stock-dying, or piece-dying, process begins after the polyester fibers have already been spun together into the material. Once the sheet of fabric is created, the color is then applied. Intense pressure is used to force the dye into the fibers to help the color last longer; another method is to dip the fibers in a vat of dye. However, it is nearly impossible to fully integrate the dye with the fibers once the material has already been formed, and most of the color remains on the outside of the thread. While this process is less expensive, stock-dyed materials are more likely to fade when exposed to intense sunlight and are more susceptible to tearing.

Solution-dyed material is dyed through the entire thread, whereas stock-dyed material is only dyed on the outside.

Key Differences

The main difference between solution and piece-dyed materials is when the dye is added to the fabric. Solution-dyed fabrics will hold their color longer due to the entire thread being dyed. Piece-dyed fabrics are more likely to fade in intense sunlight due to only the outer layer being dyed.

Coverstore Solution-Dyed Materials

Our outdoor furniture covers are available in two solution-dyed material collections — Ultima and Prestige. Our grill, TV, and equipment covers are only available in our solution-dyed Ultima collection (for now!). These covers are ideal for extreme direct sunlight, heavy snow and rain, and high winds.

If you are shopping for a vehicle or powersports cover, our WeatherTite Max material is the way to go if you are looking for a solution-dyed cover.

If you are shopping for a vehicle or powersports cover, our WeatherTite Max material is the way to go if you are looking for a solution-dyed cover.

Coverstore Stock-Dyed Materials

Our outdoor furniture, grill, TV, and equipment covers are available in one stock-dyed material — Elite. These covers are ideal for moderate direct sunlight, moderate snow and rain, and moderate to high winds.

If you are shopping for a vehicle or powersports cover, our WeatherTite Prime and BlockTite (including Basic, Prime, and Max) collections will provide the protection you need.

View our Outdoor Material Comparison Chart and Vehicle Material Comparison Chart for more details.

If you are shopping for a vehicle or powersports cover, our WeatherTite Prime and BlockTite (including Basic, Prime, and Max) collections will provide the protection you need.

View our Outdoor Material Comparison Chart and Vehicle Material Comparison Chart for more details.

Featured Categories

Additional Resources

Explore the articles below to find out more about our covers.